Lego axles, in addition to connecting pegs, will be a crucial element of any robot you choose to construct. Whether used for structural support, or connecting two wheels along a single axis, lego axle beams have hundreds of important applications.

Axles come in about a dozen different sizes, and they geometry (unsurprisingly) meshes well with other lego blocks. It's not easy to determine spacing rules for beams, because most of the time spacial distances are dictated by the axle itself!

In my post about differential drives, we detailed how you can connect wheels on two separate axles; however keeping them aligned in the same order, spinning independently. You can also use wheels on the same axle, so that it will spin by itself along with the attached wheels, however this construct has many limitations when it comes to application in advanced topics.

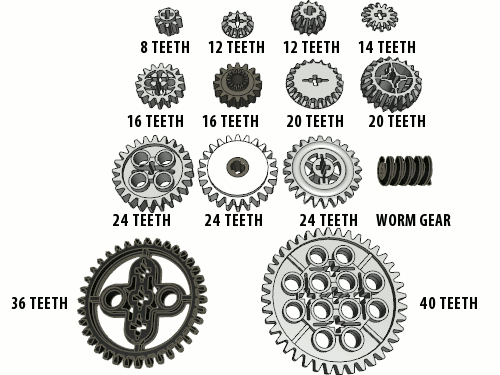

As mentioned above, the geometrical construction of axles coincide nicely with corresponding lego parts. Here's an example of a gear run through an axle, all held in place by a supporting beam block. I thought it illustrated the different relationships between the parts nicely:

Axles come in about a dozen different sizes, and they geometry (unsurprisingly) meshes well with other lego blocks. It's not easy to determine spacing rules for beams, because most of the time spacial distances are dictated by the axle itself!

In my post about differential drives, we detailed how you can connect wheels on two separate axles; however keeping them aligned in the same order, spinning independently. You can also use wheels on the same axle, so that it will spin by itself along with the attached wheels, however this construct has many limitations when it comes to application in advanced topics.

As mentioned above, the geometrical construction of axles coincide nicely with corresponding lego parts. Here's an example of a gear run through an axle, all held in place by a supporting beam block. I thought it illustrated the different relationships between the parts nicely:

.jpg)